Primary Metals

Timken Primary Metal Industry Solutions

With more than a century of knowledge and innovation, Timken has established itself as a leader in designing, manufacturing, and applying high-performance engineered bearings for the most challenging applications in the metals industry. Timken ensures consistent performance and reliability through a unified global quality system across all manufacturing plants.

In 2023, Timken joined forces with American Roller Bearing, combining over a century of expertise to offer the metals industry a comprehensive portfolio of bearings and industrial motion products. This partnership enables Timken to support the complete life cycle of metals applications, delivering solutions that optimize performance and lower total costs. Leveraging extensive application knowledge, Timken's dedicated metals specialists provide on-site industry-specific expertise, addressing challenges from increasingly demanding duty cycles to evolving environmental factors as the metals industry adapts to the needs of the market.

TIMKEN HIGH-PERFORMANCE SOLUTIONS FOR METALS APPLICATIONS

Timken provides dedicated application engineers coupled with on-site metals specialists and service engineering expertise to support the metals industry’s most challenging environments. With extensive knowledge across a wide range of applications, Timken’s engineering teams work closely with customers to optimize system performance, address unique operational challenges, and enhance overall productivity. From duty cycle analysis to environment-specific solutions, our experts are ready to collaborate on even the most demanding applications, helping customers achieve lower total cost of ownership and extended equipment life.

In addition to personalized engineering support, Timken offers a specialized Rolling Mill Industrial Training Program. This comprehensive program educates maintenance and reliability teams on best practices to minimize downtime and reduce maintenance costs for rolling mills. Participants receive hands-on instruction from Timken service and application engineers, covering essential topics such as bearing fundamentals, rolling mill configurations, damage analysis, installation techniques, and lubrication. The program combines classroom learning with practical, real-world training to equip teams with the skills needed to maximize uptime and enhance operational efficiency in metals processing environments.

Solutions for the Primary Metals Industry

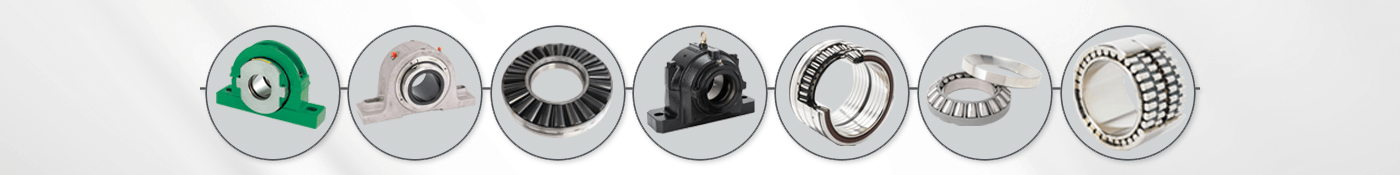

TIMKEN® SOLID-BLOCK MOUNTED BEARINGS

Timken’s solid-block mounted bearings provide unmatched protection with their high-performance triple-barrier seals, robust steel housings, and locking collars. These bearings are engineered to handle both radial and axial loads while managing misalignment. Suitable for demanding metal processing applications, they ensure durability and minimal maintenance requirements.

TIMKEN® FOUR-ROW TAPERED ROLLER BEARINGS

Timken® and American Roller Bearing four-row tapered roller bearings are designed for the rigorous demands of metal rolling mills, particularly in work and backup roll positions. The TQOW model includes slots on the cone faces to enhance lubrication access, reducing wear and increasing service life. The TQITS model, suited for high-speed rolling mills, features a continuous tapered bore through the inner races, allowing for a secure interference fit. These bearings provide high load capacity, durability, and optimized performance under the intense conditions of metal processing.

TIMKEN® SEALED ROLL NECK BEARINGS

Timken® and American Roller Bearing sealed roll neck bearings are engineered to withstand high-speed operation and harsh rolling mill environments. These bearings feature integrated seals with optimized contact geometry, providing advanced protection against contaminants while maintaining lubrication. The case-carburized components enhance toughness and fatigue life, making these bearings ideal for metal rolling mills where durability and performance under heavy loads are essential. Improved surface finishes further contribute to enhanced lubrication performance and reduced maintenance requirements.

TIMKEN® THRUST TAPERED ROLLER BEARINGS

Timken® and American Roller Bearing thrust tapered roller bearings are designed for applications requiring high thrust capacity with true rolling motion, minimizing skidding and sliding for extended bearing life. These bearings feature a full roller complement, which maximizes load-bearing capacity and reliability in demanding applications like screw down thrust positions in rolling mills. The steep contact angles of these bearings effectively handle heavy axial loads while maintaining stability, making them ideal for high-stress environments in metals processing.

TIMKEN® THRUST SPHERICAL ROLLER BEARINGS

Timken® thrust spherical roller bearing are engineered to deliver high thrust capacity with low friction and continuous roller alignment, even when the shaft and housing experience misalignment. These bearings feature spherically contoured rollers, which effectively accommodate heavy axial loads while supporting moderate radial loads. The optimized bearing geometry enhances dynamic load ratings and improves lubrication, making these bearings well-suited for backup roll applications and other high-load environments in metals processing.

TIMKEN® SAF/SNT PLUMMER BLOCK MOUNTED BEARINGS

Constructed from durable cast iron or ductile iron, Timken SAF/SNT plummer block mounted bearings come in two- and four-bolt configurations with robust sealing and locking options. These bearings extend service life and reduce maintenance needs, making them ideal for applications requiring high reliability in harsh environments, such as rolling mill run-out tables.

Timken® Mounted Split Cylindrical Bearings

Timken® offers a wide selection of mounted split cylindrical bearings designed to boost your equipment's uptime and cut maintenance costs. These bearings handle high speeds and loads, featuring robust designs and specialized cages for longer life. Their split design simplifies installation and replacement, minimizing downtime compared to traditional bearings.

DISCLAIMER: The above content is provided by the supplier. Applied® does not guarantee the accuracy or timeliness of the content.

The above content is provided “AS IS”, AND ANY AND ALL EXPRESS AND IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS ARE HEREBY EXCLUDED.

All warranties, if any, are solely from the supplier.

Find a Service Center

Find a Service Center